Brushless DC motors provide high power in a small package. Oriental Motor manufacturers a wide range of AC motor and brushless DC (BLDC) motor products. So why choose one technology over the other? There are several key differences between the different technologies.

Motor Construction

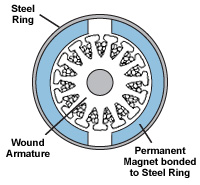

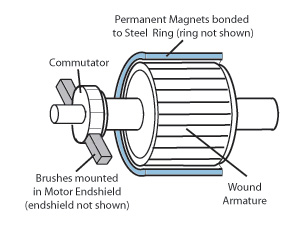

Brushed DC motors depend on a mechanical system to transfer current, while AC and brushless DC gear motors use an electronic mechanism to control current. The brushed motors have a wound armature attached to the center with a permanent magnet bonded to a steel ring surrounding the rotor. As the brushes come into contact with the commutator the current passes through to the armature coils.

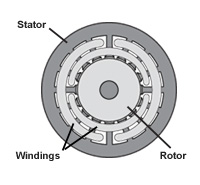

AC induction motors and BLDC motors do not depend upon the mechanical system (brushes) to control current. The AC and BLDC motors pass current through the stator (electromagnet) which is connected to AC power directly or via a solid-state circuit.

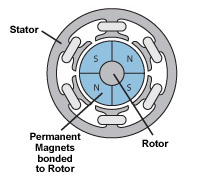

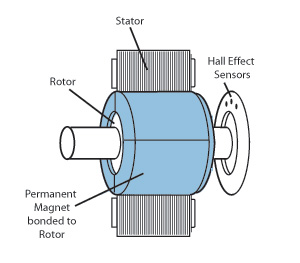

In AC induction motors the rotor turns in response to the “induction” of a rotating magnetic field within the stator, as the current passes. Rather than inducing the rotor in a brushless DC motor, permanent magnets are bonded directly to the rotor, as the current passes through the stator, the poles on the rotor rotate in relation to the electromagnetic poles created within the stator, creating motion.

| Brushed Motor Construction | AC Motor Construction | Brushless Motor Construction |

|  |  |

Efficiency

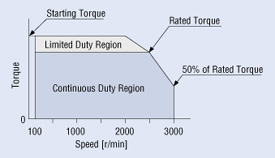

The efficiency of a system is defined as the amount of output received, as a percentage of what was input into the system. Therefore, when we talk about the energy efficiency of brushless DC (BLDC) motors, we are saying that we can obtain a relatively high amount of mechanical power, in return for the electrical power that we use.

All three technologies have power loss in the form of I-R losses. DC motors utilize permanent magnets so none of their energy needs to be used in the creation of an electromagnet as in AC motors. The energy used by AC motors to create the electromagnet decreases the efficiency of the AC motor in comparison to the DC motors.

At the same time, BLDC motors are considered more energy efficient than brushed DC-motors. This means for the same input power, a BLDC motor will convert more electrical power into mechanical power than a brushed motor, mostly due to absence of friction of brushes. The enhanced efficiency is greatest in the no-load and low-load region of the motor’s performance curve.

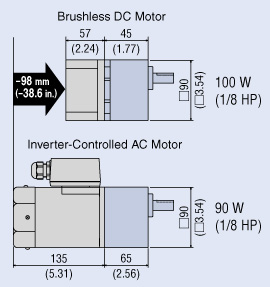

A BLDC motor, for the same mechanical work output, will usually be smaller than a brushed DC motor, and always smaller than an AC induction motor. The BLDC motor is smaller because its body has less heat to dissipate. From that standpoint, BLDC motors use less raw material to build, and are better for the environment.

Service and Maintenance: DC vs. BLDC

Brushed motors are not only larger than their brushless counterparts, they also have a shorter service life. The brushes in the brushed motor are usually made of carbon or graphite compounds which wear during use. These brushes will require maintenance and replacement over time, so the motor will need to be accessible to ensure continued service. As the brushes wear the not create dust but noise caused by the rubbing against the commutator. Brushless motors have longer service lives and are cleaner and quieter because they do not have parts the rub or wear during use.

| Brushed DC Motor | Brushless DC Motor |

|  |

Speed Stability

Hall-effect sensors built in the BLDC motor detect the change in polarity from an N pole to an S pole as the rotor is spinning. Based on the time between state changes, the rotor’s speed is determined. This information is then fed to the drive circuit to adjust the speed of the switching sequence.

High Speed Operation